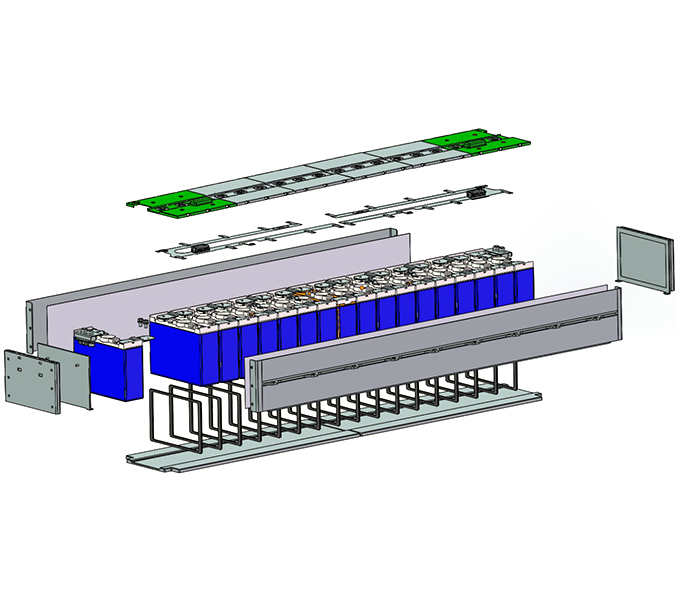

PACK disassembly

- Product Details

PACK disassembly process

- Remove the conductive copper plate: manually remove the conductive copper bar screws and remove the conductive copper bar

- Remove the liquid cooling pipe: remove the liquid cooling pipe connector

- Manual re-inspection: manual inspection and pinch accessories, manual confirmation of product information, and input the information to the next station to facilitate automation

- Remove the fixing screws of the module: a six-axis robot with CCD removes the screws that fix the module

- Manual inspection: reserve screw stations for manual removal of modules

- Pry the module: check the safety of a single module, and pry each module (disconnect the glue)

- Pry open the liquid cooling tube: manually pry open the bonding between the module and the liquid cooling tube

- Hoisting module: manually hoist the battery module to the module transfer conveyor line

- Hoisting PACK pallets: manually hoist the PACK box to the side to be transferred out

- Empty tooling board reflow: empty tooling board reflows through the lower layer of the elevator

PACK dismantling drum line

Previous:No more

©2019-2029 Dongguan Guangya Intelligent Technology Co., Ltd. All Right Reserved.